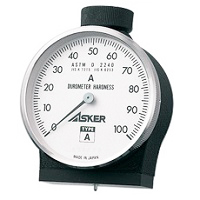

Product

Hardness

By using of the stop hand, you can read a maximum value with great ease. This tester provides a most useful accurate hardness measurement of samples with stress relaxation (the indicated value dropping immediately after pressing) or samples whose hardness cannot be read from start. You can also read the current indication simultaneously with maximum value with the help of the stop head.

Perfect for hardness check on narrow/ curved surface of quenched material

Narrow/ curved surface can be measured by small diameter probe

Hi durability - More than 1 million measurements.

Measurement in just 2 seconds.

Static loading method with Vicker indenter.

Tiny indentation (approx. 0.1mm).

Measurement is not effected by material/ mass of measuring base

• Auto turret allows one-touch operation for troublesome lens-indenter-lens changeover required in the measurement.

• Large LCD touch panel with a clear display and back light can perform various data processing and other function

• Loading mechanism with no fluctuation, “capable to hit aimed portion”, is highly evaluated.

• Knoop hardness calculating functions can be changed over with a one touch panel operation. (HK diamond indenter is optional)

• Loaded with a LCD display with backlight. The hardness tester secures very clear and high visibility

• After setting the reference load, the test load is applied automatically . (Manual start is also possible)

• Reference load can be easily set with a bar graph display on the bright screen and electronic sound. More over, an error-preventing device is also mounted.

• The new function LCD Touch Screen Visibility and operation changed to a LCD Colour Touch Screen, In addition to conventional HV, HK measuring mode.

• Fracture toughness (KC), Light Load Brinell, X-Bar, Cylindrical Correction were added into the measuring mode.

• The turret can hold 2 indentor & 4 Objective Lens.

• Wide test load range of 9 levels for Type A model & 12 levels for Type B Model.

• Measuring unit and Minimum graduation can go to 0.01micron.

• In LCD Model MMT-XLCD series saves space against CRT Monitor, provide clear image and also reduce eyes fatigue.

• Available for hardness measurement with one-push operation and output to personal computer and printer is executable.

• High repeatability of the hardness readings is assured from the flexible joint function and a constant pressure loading mechanism.

• Stable measuring position can be obtained constantly with double slide shaft.

• When attempting to measure hardness manually , inconsistent pressures and/ or speeds are used while pressing the indentor and presser foot. This causes a problem of deviation in measured results.

• To solve this problem, CL-150 Series constant pressure/speed loaders have been developed. Applicable standards refer to this type of loader as a ‘Durometer Holder.’

• ASKER Model F - ASKER Model FP

Exclusive type for foam materials, allowing measurement by placing the tester on the object o measurement.

In addition to Model F, Model FP is available for powder puff.

• ASKER Model CS

This features larger indentor and a more strong spring compared to ASKER C, thereby making it more suitable for poystyrene foam.