The RCA Abrasion Wear Tester is used to test surfaces for resistance to abrasion and wear. Typically used on painted or plated organic finishes, foil, and inked key pad lettering. This tester is widely used as a standard for many silicone key pad and membrane switch manufacturers. This abrader is used as a standard to the auto, appliance, cell phone, plastics, and coating industries. It uses an inexpensive roll of throw away abrasion paper. All build‐up error is eliminated and consistent readings are easily obtained

Product information

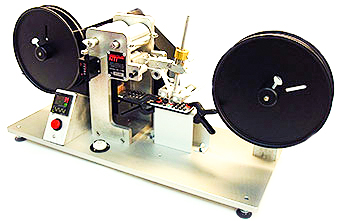

Norman Tool RCA Abrasion Wear Tester

• Easy set‐up and operation

• Automatic shut‐off

• Repeatable and consistent results

• 3 load settings

• Abrasion debris does not affect test

• Continuously uses inexpensive unused abrasive media

• Dimensions: 10″ x 24″ (40mm x 95mm)

• Weight: 37 lbs. (16.8 Kgs)

• Power: 120v/220v/240v

• Paper Velocity: 2.1 in/sec

• Cycles per Min.: 20 cycles (approx.)

• Load Settings: 55, 175, or 275 grams

• Max Samples Size: Approx. 7‐1/2″ to 9″ wide (depends on height), pass through design

• 7‐IBB‐CC‐110V 110V RCA Abrasion Wear Tester

• 7‐IBB‐CC‐220V 220V RCA Abrasion Wear Tester

• 7‐IBB‐CC‐240V 240V RCA Abrasion Wear Tester

• 1116‐P‐10 Abrasion Wear Paper—Standard Factor, 11/16″ Wide 10 Rolls

• 1116‐P‐40 Abrasion Wear Paper—Standard Factor, 11/16″ Wide 40 Rolls

• 0104‐P‐20 Abrasion Wear Paper—Standard Factor, 1/4″ Wide 20 Rolls

• 1116‐M‐10 Abrasion Wear Paper—High Abrasive, 11/16″ Wide 10 Rolls

• 1116‐M‐40 Abrasion Wear Paper—High Abrasive, 11/16″ Wide 40 Rolls

• OR‐01 Rubber O‐Ring for Abrader Wheel—Pack of 32

• CK‐01‐175 Calibration Kit Tested at 175g for Customer Calibration Check

• CK‐01‐275 Calibration Kit Tested at 275g for Customer Calibration Check

• D‐C Dust Cover

• GA‐01 O‐Ring Wheel Alignment Tool